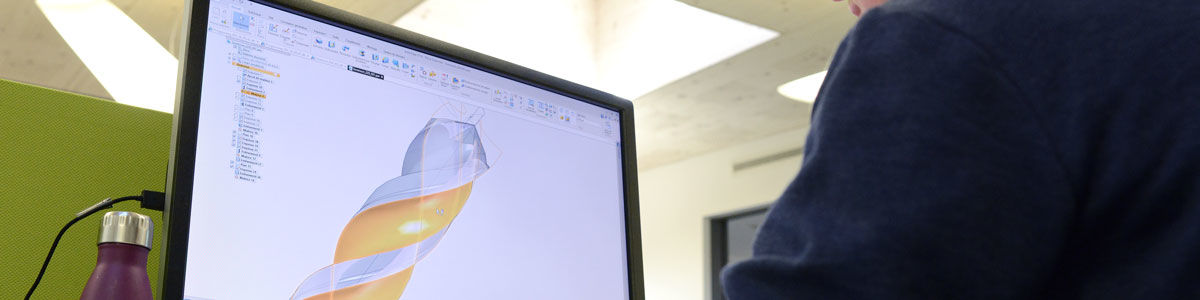

To cope with our many projects and for several years, a Research & Development department is at your service for developing the optimized tool for your application.

Our engineers put all their energy to:

Bélet tools are made to last!

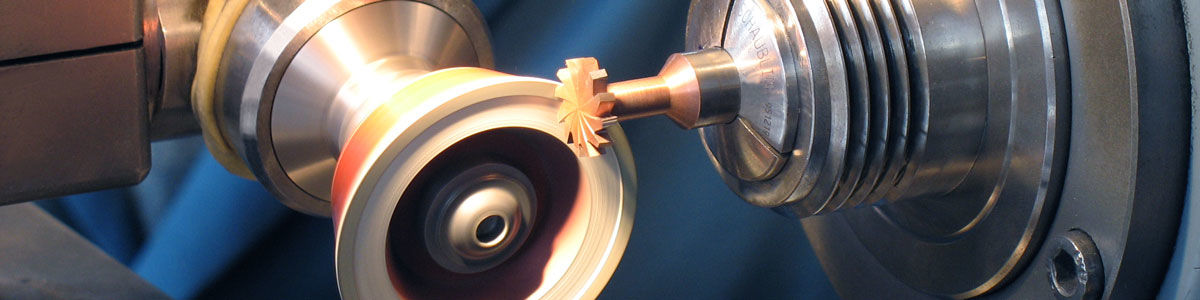

Most tools can be reconditioned, either if manufactured by Bélet or by our competitors. For instance:

Reconditioning allows the renewal of your tool at low cost and within a short timeframe. Depending on the dimensions of the tools, of the cost of a new tool or on the condition of the used tools, it may happen that reconditioning is not possible or judicious. In this case, our specialists will contact you to propose an alternative.

Reconditioned tools can also be coated again.

Reprofiling

Profiled tools with constant or logarithmic relief can also be reconditioned on our specialized machines. Form tools with a logarithmic profile have the advantage that they can be resharpen while keeping their exact original profile.

In addition to the common micrometers and profile projectors, Louis BELET SA has cutting edge technology for tool control:

We are able to provide acceptance test certificates 3.1 according to DIN EN 10204:2005-01

The technical department of Louis BELET is here to assist our customers.

You can send us your requests by fax: +41 (0)32 474 45 42 or e-mail: offres@louisbelet.ch

On reception of a tool drawing, machined part drawing, example of an existing tool, or a simple had sketch, our team will make a final drawing of an optimised tool and will submit it to you for validation before execution.

Louis Bélet recommends using this problem solving's site:

This tool allows reliable and interesting experimental approaches. It is innovative in its own way to simplify the consideration of various factors for problem solving. Simply get in touch by sending an email to info@caravelcut.com mentioning Louis Bélet, in order to embark on the adventure of intelligent problem solving.

LOUIS BELET S.A

Les Gasses 11

2943 Vendlincourt

SWITZERLAND

TEL.: +41 (0)32 474 04 10

FAX: +41 (0)32 474 45 42

www.louisbelet.ch

info@louisbelet.ch