Technical Features

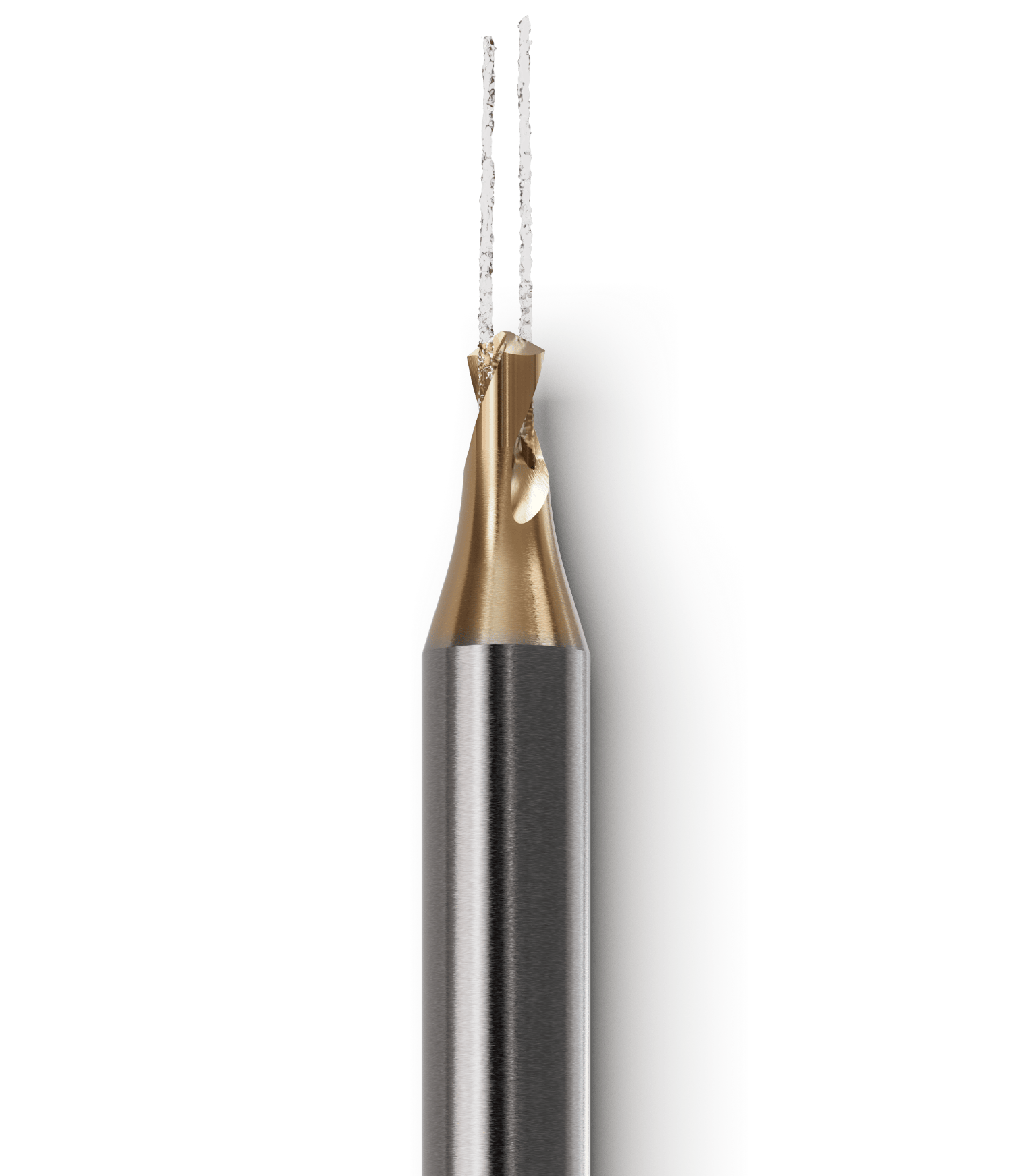

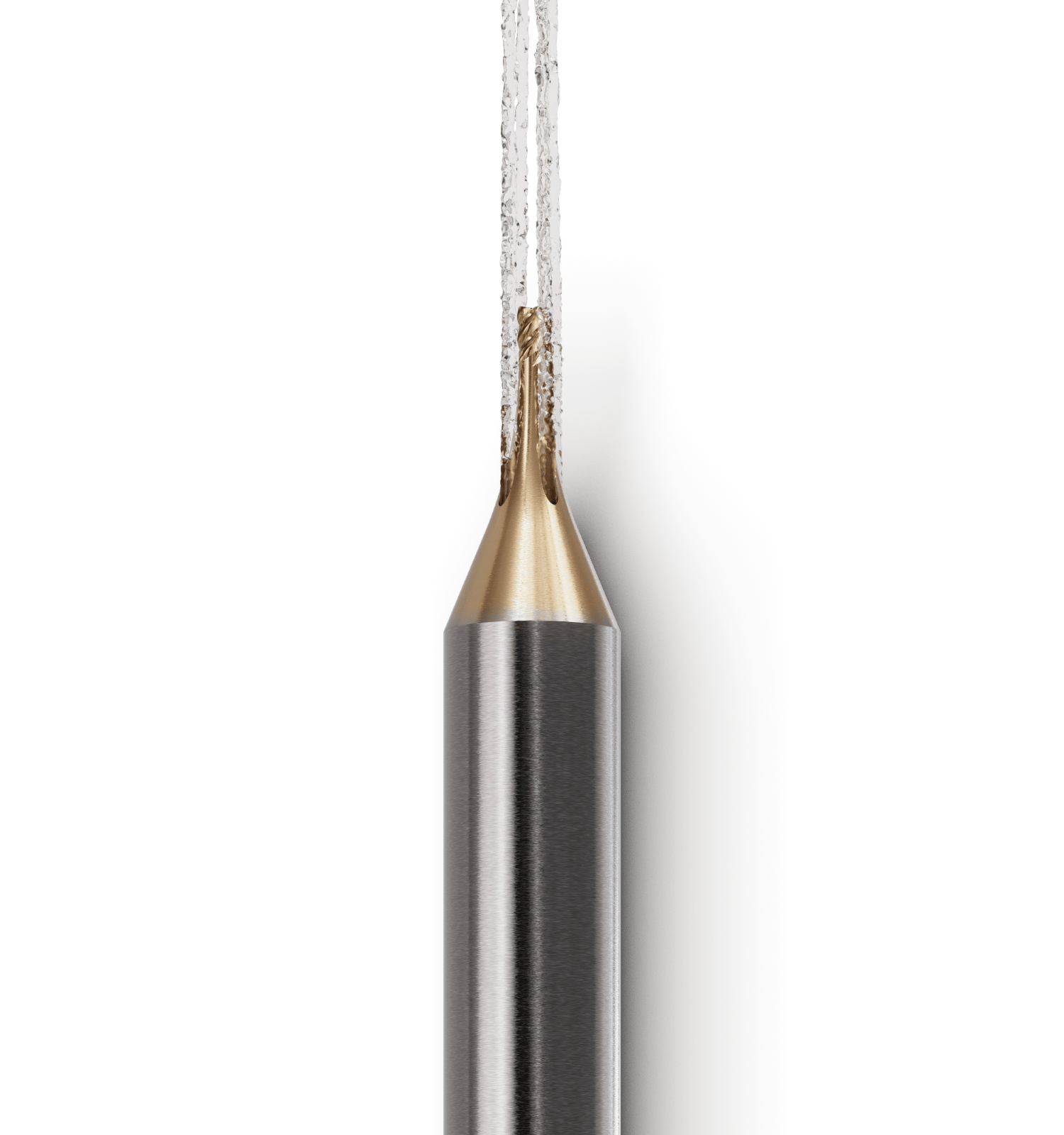

Innovative Internal Lubrication

Ensures optimal cooling and efficient chip evacuation, extending tool life, whether for drilling or milling.

Optimized Geometry

Designed to reduce cutting forces and improve precision, delivering consistent results across a wide range of materials.

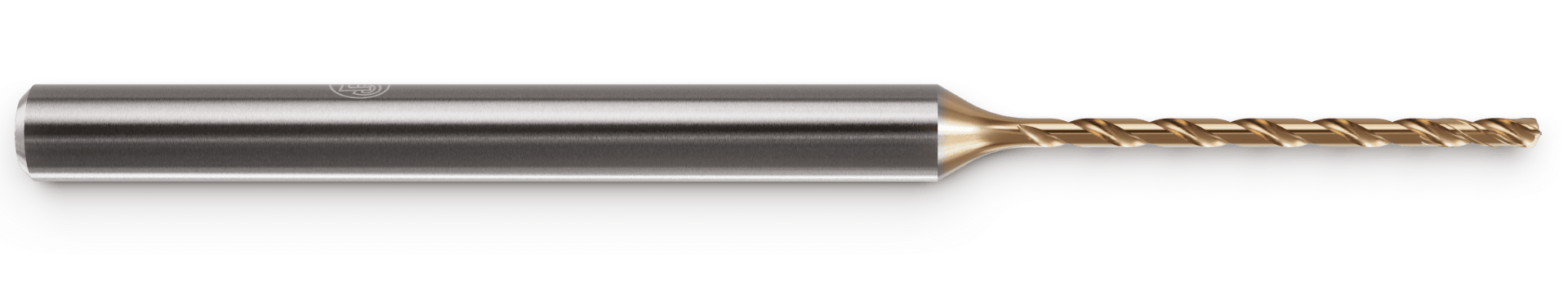

High-Quality Materials

Manufactered from specific micro- grain carbide, ensuring increased performance, even in the most resistant stainless steels and superalloys.

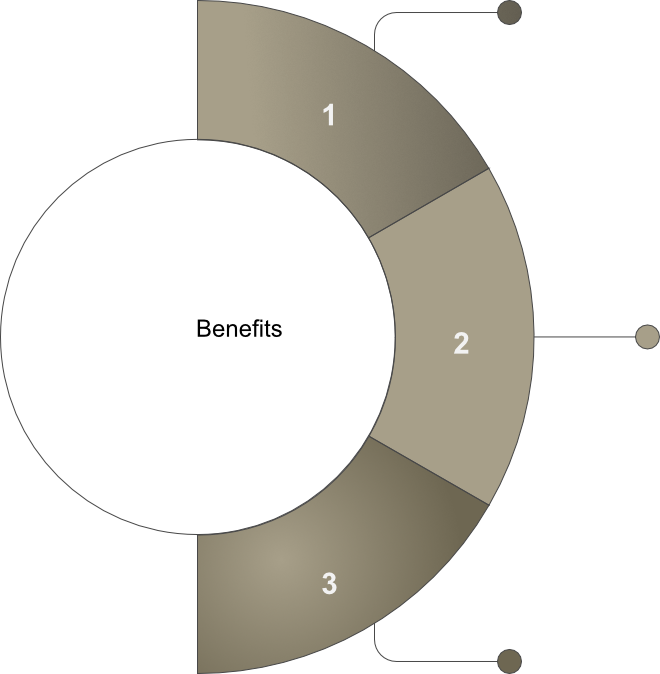

Increased Productivity

Significant reduction in cycle times thanks to superior cutting speeds, whether for drilling or milling.

Superior Drilling Quality

Improved hole and surface precision and cleanliness, minimizing rework and ensuring consistent results.

Exceptional Durability

Increased tool longevity, reducing replacement costs and downtime, even in the most demanding machining environments.