The service life, surface finish and machining of particularly abrasive materials often lead to frequent set-up times or tool changes.

The use of PCD tools can in many situations facilitate the processing and machining of the workpieces.

The initial price of PCD tools may be a deterrent for some. However, the time saved on tool changes and the resulting machine downtime ultimately speak in favor of PCD tools when considering part cost.

Several PCD tool suppliers are present on the market. As usual, Louis Bélet designs, produces and markets tools of the highest quality in order to offer the most efficient solutions! The grinding by diamond wheel or laser are the technologies most frequently used in the realization of PCD tools.

Whether it is for its stock of standard PCD tools or for customized solutions, Louis Bélet is your ideal partner in your quest for process optimization.

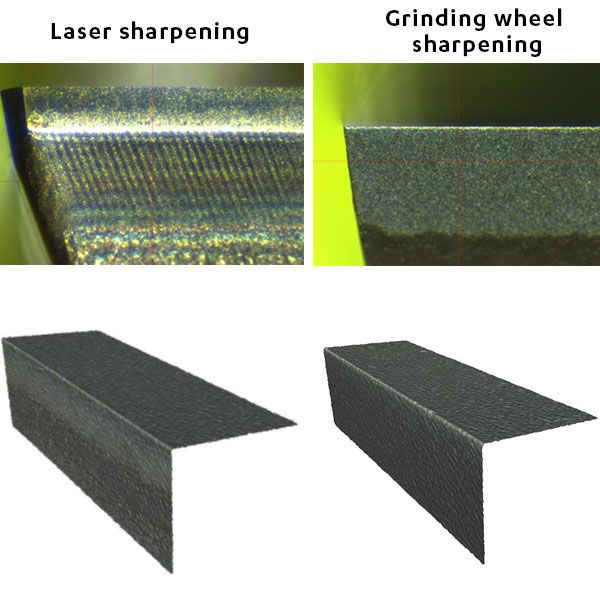

The quality of machining depends directly on the sharpness of your cutting tool.

At Louis Bélet, we use only the best materials with the smallest possible grains.

Although only laser sharpening can cut the diamond grain as it is removed by the grinding wheel, the combination of the fineness of the grinding wheel with the fineness of the PCD grain gives our tools the best quality available on the market.

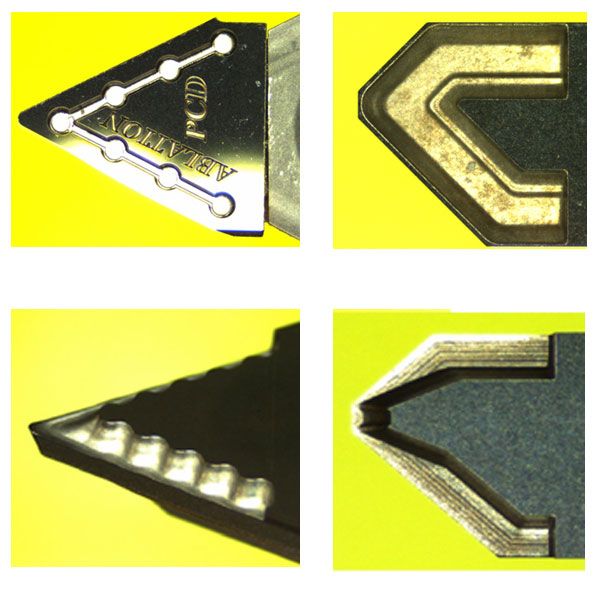

In the case of special PCD tools, the laser allows the realization of unprecedented shapes!

As you know, Louis Bélet does not produce standard turning inserts.

However, we offer our customers the possibility of producing inserts with the desired geometry in PCD.

Moreover, our knowledge in programming our laser grinding machines allows us to realize the geometries of chip breakers according to your needs.

The laser ablation of PCD is the technique used for the realization of these inserts.

Let your imagination run wild and submit your requests to us!

Innovation is in Louis Bélet's DNA. We have listened to market demands and have decided to produce PCD tools in monobloc. The first family of tools to use this manufacturing process is the internal whirler.

Offered as standard from S 0.80 to M 3.0, the performance of this tool will exceed your expectations, whether in highly abrasive materials such as platinum, composite or your high-volume production in brass and especially in lead-free version!

New types of solid PCD tools will soon be added to our product line! Stay tuned!

One of Louis Bélet's great strengths is the production of tools customized to your needs. PCD tools are no exception to the rule and our R&D department regularly develops new designs to meet the requests of the most demanding customers.

Whether it is for simple dimensional modifications of standard tools or for the realization of personalized shapes, do not hesitate to challenge us!

LOUIS BELET S.A

Les Gasses 11

2943 Vendlincourt

SWITZERLAND

TEL.: +41 (0)32 474 04 10

FAX: +41 (0)32 474 45 42

www.louisbelet.ch

info@louisbelet.ch