Whether for dental, medical, watchmaking or any other market, making gears with a high tooth height and a thin base makes the parts brittle and the teeth can bend. This problem can be further accentuated if the thickness of the gear is minimal.

Aware of a customer's problem, Louis Bélet's teams have found a way to produce this type of gearing.

It is our new AltoBasso technology that solves this problem. The process consists in cutting the profile in two steps, first the top part and then the base of the profile.

All the know-how and knowledge of Louis Bélet SA - from the technical department to the production - have been combined for the development of this tool!

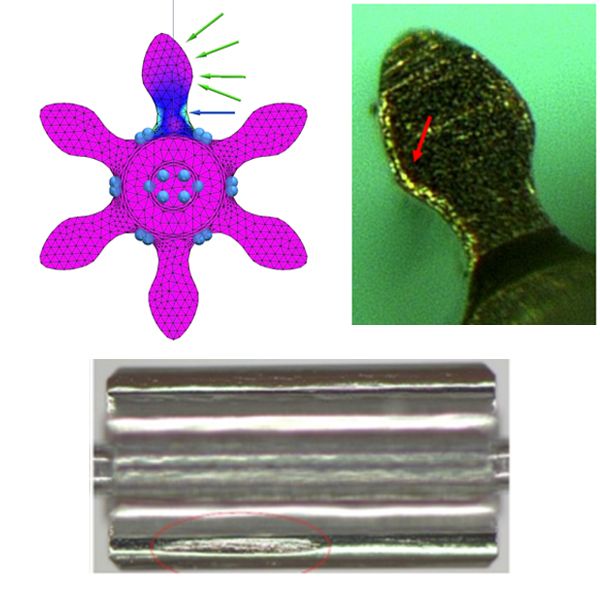

The production of a profile with both a high tooth height and a thin base induces consequent forces during the cutting of the teeth as can be seen in the finite element simulation below.

The resulting problems are multiple. This can cause material to be torn off at the top of the teeth in a random manner (as can be seen on the bottom photo).

Another problem often seen is aliasing on one side of the tooth (similar as burrs). In addition, the teeth often come out of production with too thin a profile.

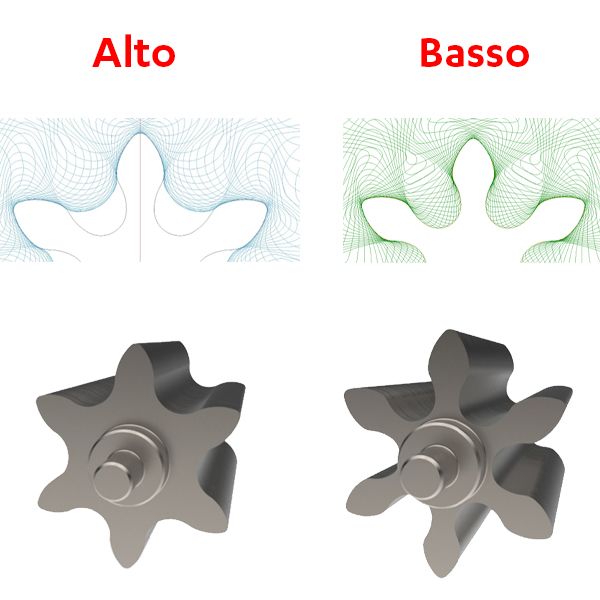

The AltoBasso technology solves this problem in two steps. The first hobbing will make the upper part of the profile only (Alto). This will reduce the stresses related to the cutting of the gear tip.

By a simple shifting of the cutter corresponding to a multiple of the pitch, the user will move from one hobbing region to another, in order to arrive at the Basso hobbing area which has the complete profile.

This way of proceeding will allow to cut the complete gear without any defect, even on very small wheels!

Once again, Louis Bélet's innovation is at the service of its customers.

The problem was complex, but our efforts have enabled us to develop this two-step cutting process.

The singularity of our in-house developed profiling machines gives us the flexibility to produce small hobs starting with a module of 0.01 (approx. 2’500 DP) up to a module of 1.5 (approx. 17 DP).

This makes it possible to produce wheels with diameters of a few tenths of a mm. This was the case in our example presented here!

The AltoBasso technology is based on a succession of hobbing of the upper part (Alto) and lower part (Basso).

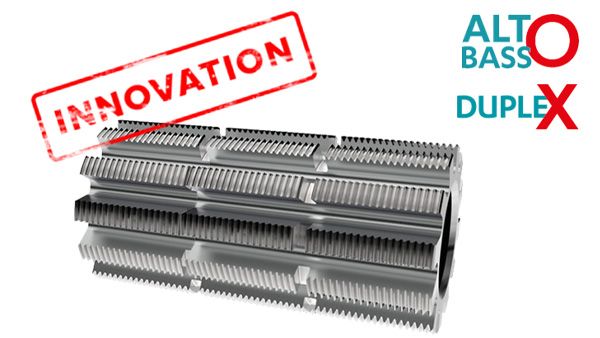

We have seen in a previous technological presentation the principle of burr-free hobbing "Duplex".

In order to achieve burr-free hobbing for high and thin profiles, the addition of the "Duplex" option is possible, resulting in a tool with 3 "stages" for sequential hobbing "Alto", "Basso" and finally "Duplex".

With Louis Bélet, innovation has no limits!

LOUIS BELET S.A

Les Gasses 11

2943 Vendlincourt

SWITZERLAND

TEL.: +41 (0)32 474 04 10

FAX: +41 (0)32 474 45 42

www.louisbelet.ch

info@louisbelet.ch