Machining of composite materials is very complex, because the characteristics of the resulting compound, depending on the added fibers or matrices, which allow to obtain the desired properties, are often very different from those of the base material.

Sometimes tough, tenacious or weather resistant, the addition of fibers, balls or matrices in carbon or glass makes this amalgam a heterogeneous whole.

For cutting tools, the coating must be specific and adapted.It is often used to improve the service life.

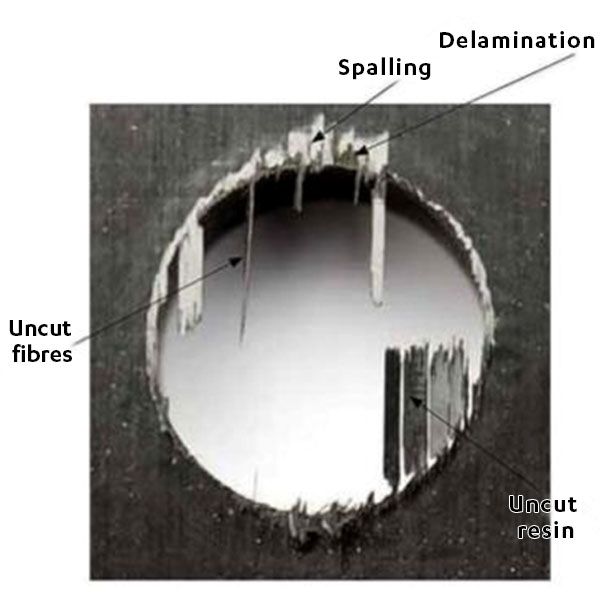

Specific cutting geometries avoiding delamination or the creation of burrs in these composite materials have been identified and studied in order to make machining more efficient.

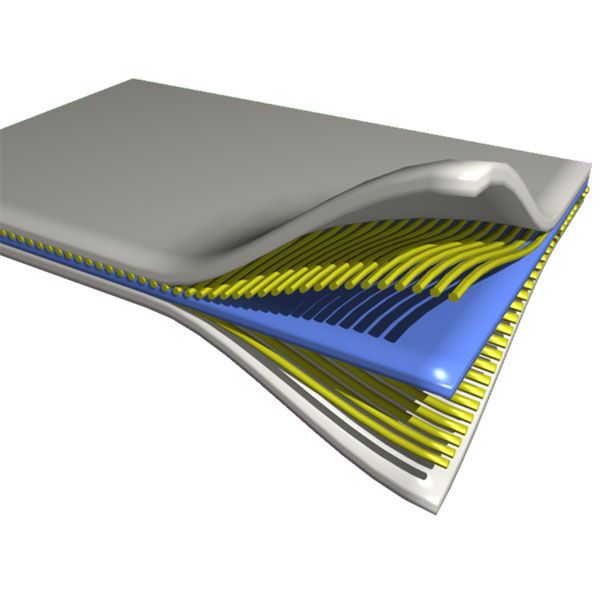

A composite materials is an assembly of at least two immiscible components whose properties complement each other. The new, heterogeneous material thus created has properties that the individual components do not have. This improvement in properties explains the growing use of composite materials in many fields.

From a machining point of view, composite materials require specific developments in order to adapt the geometry of existing tools to the new properties added by the fillers or reinforcements!

The use of composite materials can be motivated by different characteristics that are missing but necessary for the base material to perform even better. Here is a non-exhaustive list:

In terms of machining problems with composite materials, the major challenges related to heterogeneous mixing are the following:

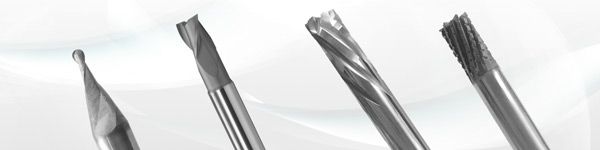

Standard or custom-made, Louis Bélet's tools are developed, produced and marketed with the utmost care and know-how.

Tools dedicated to composite materials are no exception to this rule.

Whether in carbide or PCD, we adopt the most demanding criteria to offer you the best tools on the market.

Our range of tools dedicated to composite materials can be consulted in our Expert Tools brochure dedicated to these materials.

LOUIS BELET S.A

Les Gasses 11

2943 Vendlincourt

SWITZERLAND

TEL.: +41 (0)32 474 04 10

FAX: +41 (0)32 474 45 42

www.louisbelet.ch

info@louisbelet.ch