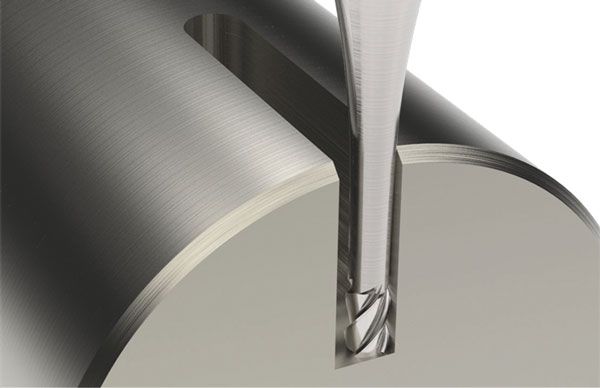

Vibrations, poor surface finish, burrs or even tool breakage are all challenges and solutions to be sought in order to obtain satisfactory results in deep micromachining and this, up to five times the tool diameter.

Some time ago, the medtech industry challenged us to design and produce a tool that would allow us to obtain an irreproachable part, while having a longer life than the competition for hexalobular prints.

Our R&D department has analyzed the weaknesses of the tools available on the market and has modified their specifications in order to achieve the goals set.

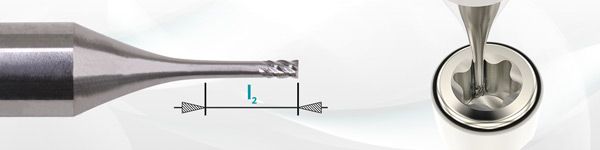

The 1430 and 1450 series are tools that allow milling in full and with significant depth.

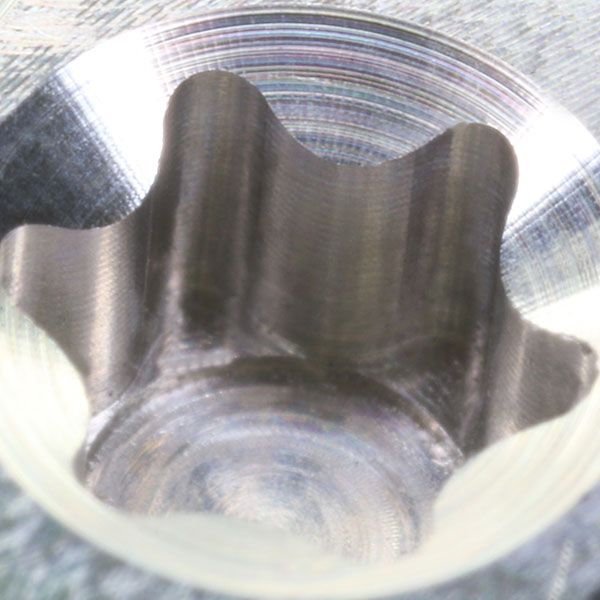

As mentioned, this series of tools was developed to make Torx® cavities in materials such as stainless steel, titanium and Chrome-Cobalt for medtech. This said, that cutter has been quickly adopted by other industries machining other materials such as gold, precious metals or even pure nickel!

As mentioned, vibration causes problems that can lead to poor results or even tool breakage.

Competitor tools offer abruptly angled clearances and therefore, possible incipient break point.

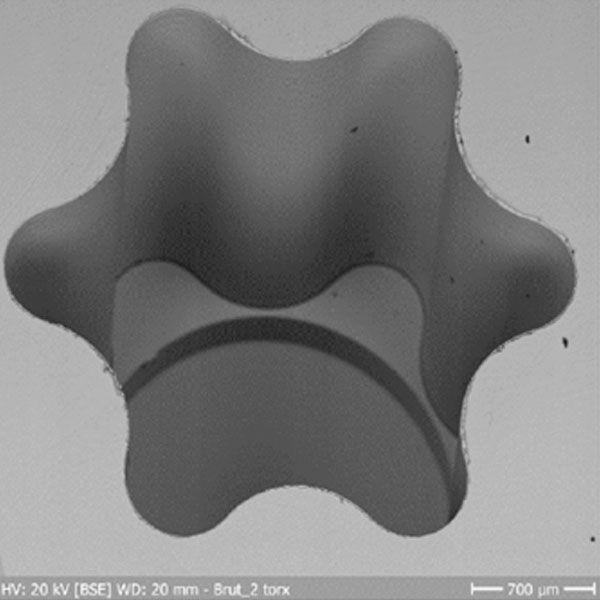

To overcome this problem, Louis Bélet's R&D team has studied the problem and developed a geometry with a succession of rays allowing optimal absorption of these undesirable vibrations.

Abow is an image taken by a scanning electron microscope showing the cutting quality of the tool.

Cutting parameters for this type of tool vary with different materials being machined. Here are some of them:

| Vc[m/min] | N[tr/min] | Fz[mm] | |

| Stainless | 50 | 32’000 | 0.003 |

| Titanium | 50 | 32’000 | 0.003 |

| CrCo | 100 | 64’000 | 0.003 |

For other materials please consult our brochure or get in touch us.

In the example of machining hexalobular cavities, the machining principle is as follows:

1. Drilling with a dedicated step drill with chamfer cone

2. Drafting using our tools 1430/1450

3. Finishing using our tools 1430/1450

This way of machining offers you optimal surface finishes and speed of execution allowing you to satisfy your customers and your return on investment.

The features of this tool 1430-1450 can be customized to your needs. Initially designed for the medical field, these tools quickly became the reference for deep micro-milling.

With diameters between 0.20 and 1.00 mm as standard, the cutting or clearance length, intermediate diameters, radii or chamfers at the end or specific coatings for various materials are some of the variations that we can offer for these tools. Put us to the test!

LOUIS BELET S.A

Les Gasses 11

2943 Vendlincourt

SWITZERLAND

TEL.: +41 (0)32 474 04 10

FAX: +41 (0)32 474 45 42

www.louisbelet.ch

info@louisbelet.ch