Skiving or internal tooth cutting has been known and widely used in the mechanical industry for many years in modules greater than 0.5 and with standard tooth shapes.

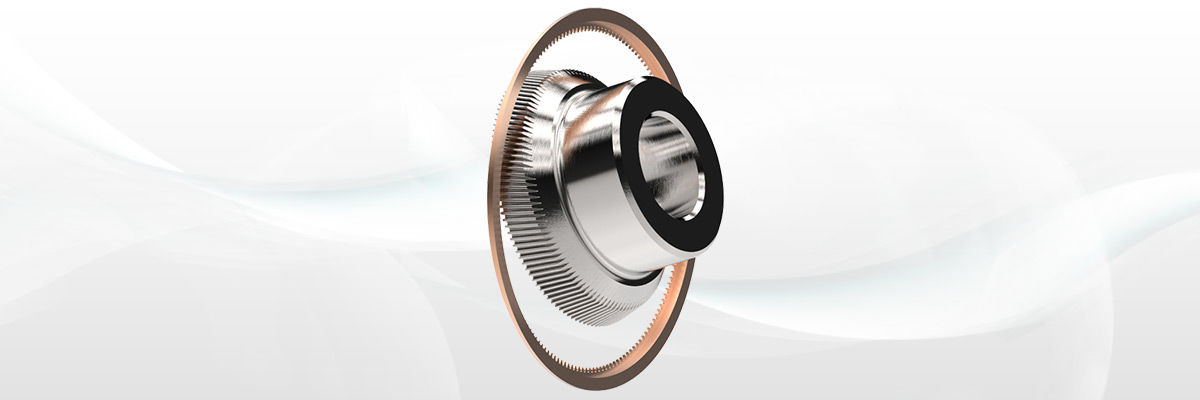

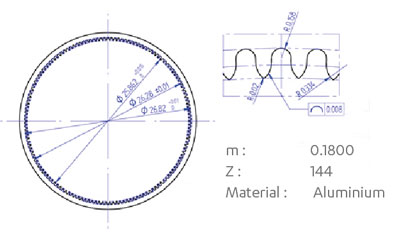

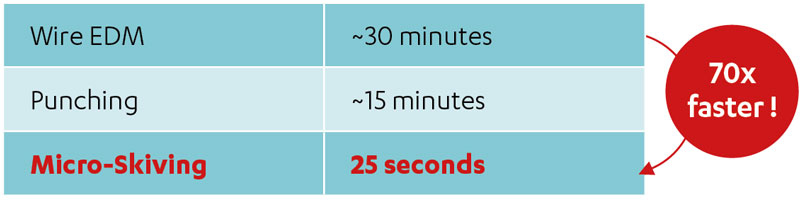

Micro-skiving has been developed to allow the use of the skiving technique for internal micro-teeth, using modules well below 0.5. The general process is the same as for the current modules but at a highly reduced scale. The stresses of precision, shape, burr and surface finish become much higher.

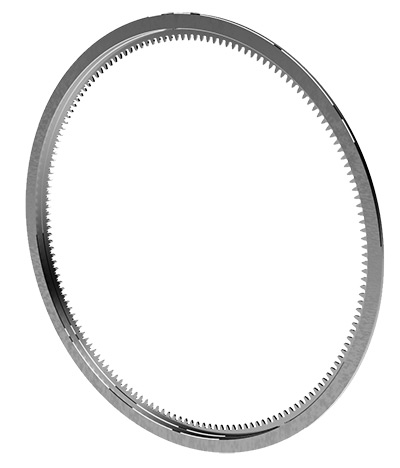

Profile heights of a few hundredths of millimeters and special tooth shapes require special tool manufacturing processes using custom software and high end grinding machines. This evolution extends the possibilities of a very fast, precise and high volume production of high quality internally toothed gears. This type of gears are increasingly used in watch movements, micro-assembly, medical pumps or gearboxes.

LOUIS BELET S.A

Les Gasses 11

2943 Vendlincourt

SWITZERLAND

TEL.: +41 (0)32 474 04 10

FAX: +41 (0)32 474 45 42

www.louisbelet.ch

info@louisbelet.ch