Whether it is for the dental, medical or any other market, the realization of special, conical or custom threads is subject to arduous programming, high machining times and complex production monitoring.

The realization of threads by polygon machining is known in several industries, including watchmaking.

The idea was therefore to use this manufacturing process and apply it to thread geometries that are as exotic as they are widespread.

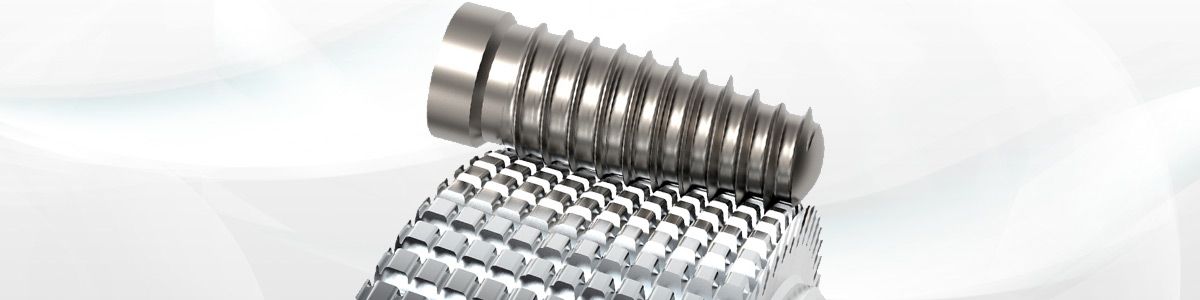

Based on the complex shape of a dental implant, the development of this tool required all the know-how and knowledge of all the sectors of Louis Bélet SA, from the technical department to production!

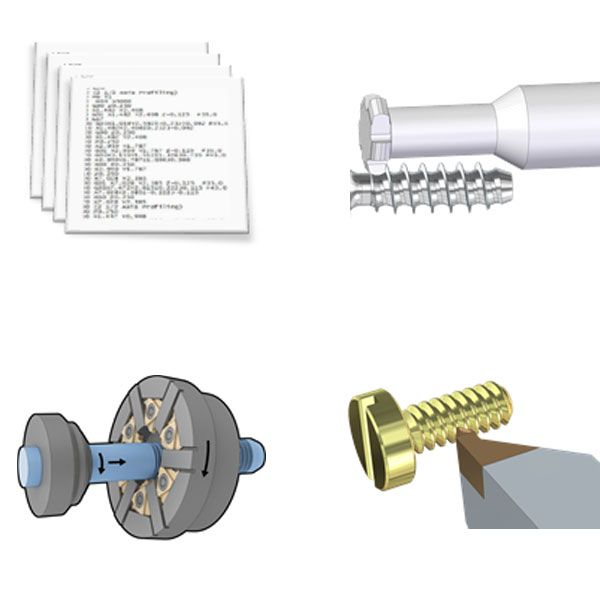

There are several technologies available to produce this special type of thread. Form milling, chasing inserts or thread whirling solutions are all proven production methods. While these techniques are effective for simple cylindrical threads, programming can become long and tedious for more complex profiles, such as threads with tapered entry or with 2 intersecting shapes.

Not to mention the machining time for this part which can take several minutes and thus represent a time-consuming step in the production of the part.

The simulation of these parts encouraged us to continue the development. However, a major unknown was the possibility of producing these tools. Indeed, the complexity of the suggested thread and its precision required all the know-how and experience of our development and production teams.

Our special machines, designed in-house, were used to produce these special thread polygon cutters.

With the use of this new tool, the complicated programming of the machine is as if integrated into the milling cutter, thus saving a lot of set-up time.

Production of the first parts was carried out on two types of machines

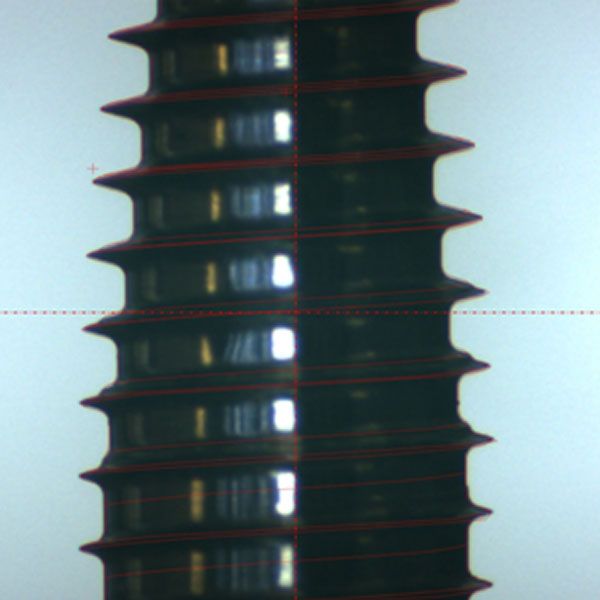

In both cases, the production of the special thread comprising a conical part and a straight part with two different thread shapes was achieved in less than 10 seconds in titanium! As can be seen in the picture above, the desired profile (in red) perfectly matches the geometry of the part! A new challenge taken up by the Louis Bélet teams!

In addition to threads with special geometries, this polygon milling technique allows us to open new possibilities, such as the production of conical, variable pitch threads or eccentric parts!

Simply contact us for any custom shape you should have!

LOUIS BELET S.A

Les Gasses 11

2943 Vendlincourt

SWITZERLAND

TEL.: +41 (0)32 474 04 10

FAX: +41 (0)32 474 45 42

www.louisbelet.ch

info@louisbelet.ch